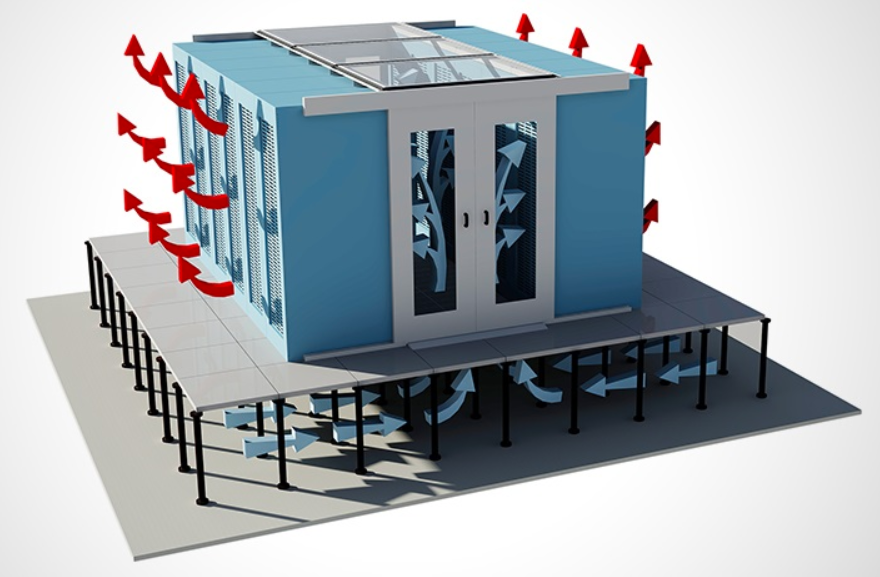

A cold aisle containment system (CAC) encloses the cold aisle, allowing the rest of the data center to become a large hot-air return plenum.

Why cold aisle containment ?

Below thermal image comparing CAC vs open aisle & it is very obvious that the difference between temperature inlet at rack bottom & top in the open aisle have reached 10.8 degree Celsius resulting in server inlet temperature of 32 degree Celsius which violate ASHRAE recommended operational temperature range

Benefits of cold aisle containment including:

- OPEX saving

- More efficient air distribution

- Uniform temperature in front of servers

- Higher return air temperature

- Increase of free cooling number of hours

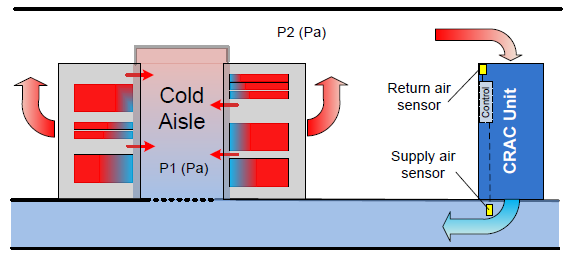

Why containment pressure control is needed ? well It’s all about air flow required by servers, since servers have variable speed fans, the cooling units air flow must be equal to servers total air flow inside the containment to avoid negative or positive pressure inside the containment as shown in below figure:

What will happen if we didn’t achieve this balance ?

a) In case of negative pressure inside the containment (P1<< P2):

- Servers aren’t getting enough air

- Hot air intrusion inside the cold aisle

- Reducing server fans life time

b) In case of positive pressure inside the containment (P1 >> P2):

- Loss of cold air outside of the containment

- Over blowing servers fans

- Reducing servers fans life time

There are two solutions for pressure control:

a) Constant pressure control:

- Pressure sensor work in the range of 15 to 20 Pa

- Each unit have its own sensor

- All units sharing readings

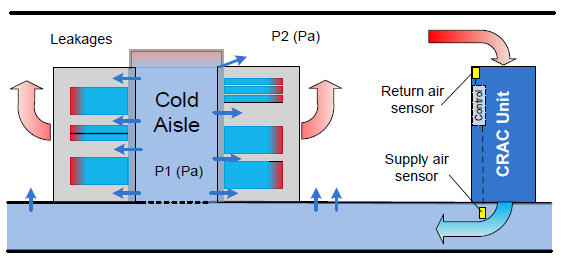

Disadvantages of pressure control:

- Focus on the differential pressure between raised floor & cooling units return

- Low sensitivity

Which may cause critical situation as shown below:

b) Smart aisle control

This solution is achieved by installing sensor box in each containment wall which continuously measure the temperature as shown below:

Concept of operation is very simple, when the sensor measure cold air temperature, it means that pressure inside aisle is positive & cold air started to escape from the opening & when the sensor measures hot air temperature, it means that pressure inside containment is negative & hot air started to leak inside the containment.

By doing this continuously the system can determine efficiently the required air flow for each aisle containment & act accordingly as shown below, which will lead to improving system efficiency & increasing components life